A story of determination and growth

How Duvall Leatherwork found its new Artisan Workshop

By: Nick Duvall, Founder

Sixteen years ago, I started Duvall Leatherwork in the basement of my home creating handcrafted leather goods. In 2006, I expanded my small startup business by purchasing a commercial building in Kingston, Pennsylvania. After 15 years of business growth, product growth and team growth, we had simply grown out of our space. It was time to expand.

I set out to purchase a property large enough to fit our growing business, which would be enough to support our retail store in Kingston and online sales. After months of searching, I was no closer than when I started. After some sound real estate advice, I began to explore leasing options.

I had always noticed the gigantic industrial complexes going up along the highways in Northeast Pennsylvania, but I paid little attention to them until I took my first tour. “This is exactly where we need to be,” I thought to myself after days of touring properties. Parking, restrooms, loading docks, security, space — home run!

For several weeks, I studied the ins and outs of leasing commercial property on this scale. I explored every detail like utilities, rent, CAM fees (which I had no idea even existed), snow removal, how many team members I would need to make this space work — the list goes on. I worked diligently and planned carefully before landing on a space that fit our needs best.

I decided that a well-maintained, 6,000-square-foot flex space from Mericle Commercial Real Estate Services has everything we need. The space is two-thirds finished with carpet, painted drywall, a kitchenette, men’s and women’s restrooms, and spacious, divided rooms for work. The other one-third is a wonderfully clean warehouse and loading dock, which is ideal for leather cutting and storage. Other than the risk factors associated with any business expansion, it felt like a no-brainer.

The team at Mericle, including owner Robert Mericle himself, helped us craft a fantastic and gracious lease agreement that fits our budget and needs. We were finally on our way to a better work environment for the team, a place where we could make even more excellent leather goods and add jobs to Northeast Pennsylvania’s growing economy.

JULY 1, Closing day

Closing day was sweltering hot. Our key hand off was scheduled for 11:30 a.m. Arriving in the Hanover Industrial Estates, I found that all of the final details had been completed, and the space was 100% ready for us to move in. After a quick final walk-through, everyone celebrated the accomplishment together and the keys were placed in my hand. It felt surreal. After everyone left, a sterile silence surrounded me. I sat and reflected on my journey to this point, never once letting any kind of self doubt enter my mind.

Returning home, I changed from my business clothes to my work clothes, then went out to rent a U-Haul for a month. We couldn’t find a moving company that was up for the challenge, so our shop foreman, Jonathan, and I decided we would move everything ourselves. Everyone dreads moving, but this was different.

Imagine moving an entire manufacturing company in less than 30 days. Tools, tables, 300-pound sewing machines, 500-pound sewing machines, inventory, materials, shelves, 3,000-pound machines. If the process of securing our new artisan workshop was hard, moving it was even harder — not to mention during one of the hottest summers on record.

JULY 26, Work begins in our new home

After weeks of back-breaking labor, we started our first day at our brand new artisan workshop. It was still coming together, but enough equipment was in place for our team members to start working in their new home.

But such a move always brings unforeseen challenges — and expenses. We quickly discovered that, when you have more space, it takes longer to get materials and tools. To solve this, you need multiple materials and tools for every workstation. We had overlooked the sheer amount of spending needed to scale our tools and equipment.

This was where the journey started to get to my head and affect my personal well being. The weeks passed. My stress grew, and I really started to feel nonhuman. I got depressed with no end in sight, but I kept moving.

In the old days, I spent my creativity on new product designs and craftsmanship. Expansion meant I had to use that creativity for a different, far less exciting purpose — scaling my business. I hired five new employees and managed and expanded our retail store in Kingston. Outside of that, I’m a husband and, yes, I needed to get sleep at night.

Weeks at that pace took their toll on my mind and body; I was not in a good place. It seemed strange to me that just a few weeks before, the journey had brought me such joy, but it was crushing me. “No pain no gain,” I told myself during never-ending weeks of physical and mental labor.

Then, almost as suddenly as it came on, I could see the end.

As the leaves started to change and the air cooled down, a calmness washed over. One by one, the chores needed to set up our new artisan workshop were finished. Team members started to find their rhythm with our new workshop. Our store in Kingston was fully staffed and selling products every day. Orders were shipping out from our website sales.

The system had a pulse. I began to pull back and watch from a distance, helping only if something really fell out of line. One night after work, I reflected on it all in silence, just like the day I was handed the keys to our first artisan workshop.

OCTOBER 14, Ribbon cutting day at our artisan workshop

The dust had settled, and we were ready to show our new space and expanded operations to Northeast Pennsylvania with a ribbon cutting. It was a wonderful morning attended by folks from Mericle Commercial Real Estate, the Greater Wyoming Valley Chamber of Commerce, elected officials from Hanover Township, local media including Times Leader and The Citizens’ Voice, and all of the team members of Duvall Leatherwork.

I explained our move, why we moved, what we do, and how we plan to grow in the future while moving through our new artisan workshop. We finished the tour by gathering for a ribbon cutting in front of our new shop. We gathered together and all shared a proud moment in the history of Duvall Leatherwork.

Now and the journey ahead

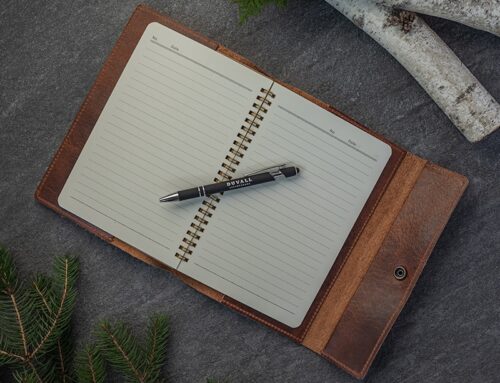

Now we enter the next chapter, life after the spotlight. We’re about the daily task of creating and crafting quality leather products that our customers feel proud to own, to hold and to touch. Now we turn all of our attention to making leather goods that work just as hard as we do — just as hard as you do.

When you use our leather goods, I hope you really can appreciate the men and women who work day in and day out bringing craftsmanship, art and joy to simple yet magnificent leather products.

As a final thought, scaling my business proved to be more of a challenge than I had ever anticipated. It was clear to me why very few people start a manufacturing business from the ground up in our modern world. It is unbelievably hard to do! I met the challenge of starting a small business, growing a business, then scaling that business into a thriving brand that creates beautiful, handcrafted American-made products.

I hope that my story resonates with anyone who has a great idea for a product or service. If you stick to your guns, work with intention and integrity, and surround yourself with incredible people who are willing to sling around quarter-ton sewing machines with you, you really can accomplish anything. I should know because this year, I did it.